Material of the Month (2013 – 2020)

Material of the Month is an ongoing project where MAKE. offers new or unconsidered materials to be used in the projects of our BURG students. The only condition to document and share the ideas and experiments which have been realized with the sponsored material. For current or upcoming “Material of the Month” editions, please check our Weblog.

Suggestions?

Of course we would like to get your opinion. What is your substance of desire? Feel free to send your suggestions to make(at)burg-halle.de and we will do our best in getting your stuff at the BURG for future experiments.

What happened so far

2020

– Material Vending Machine: Corona created the “Materialautomat”

2019

– Material of the Month: Scrap Glass

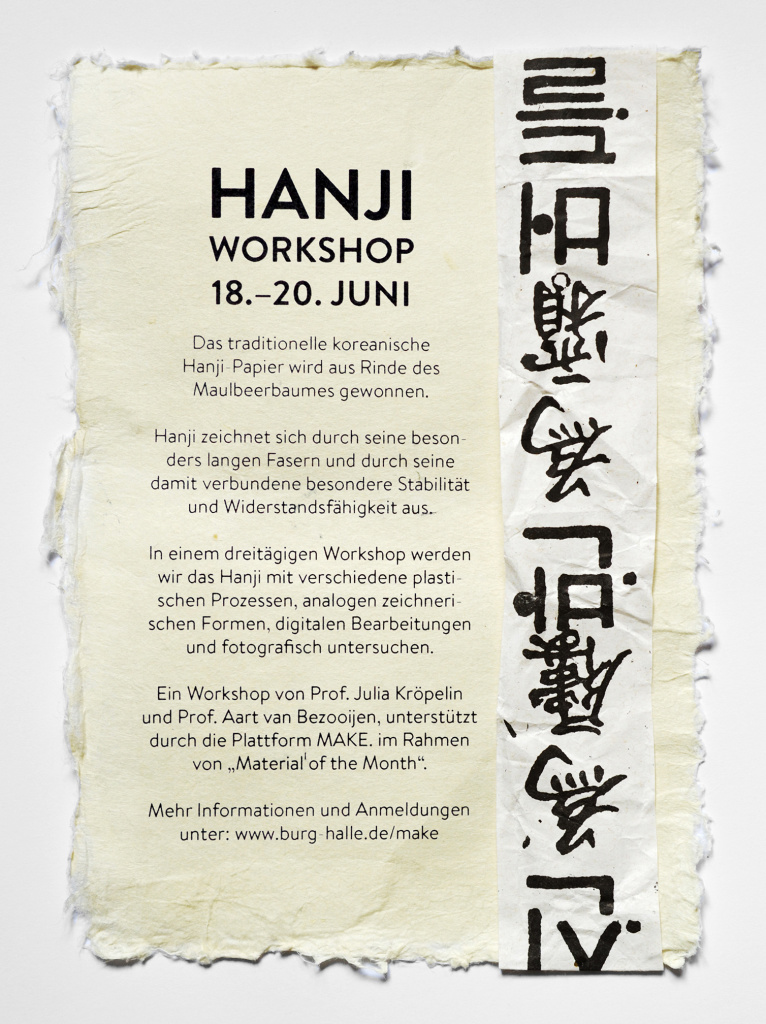

– Material of the Month: Hanji Paper

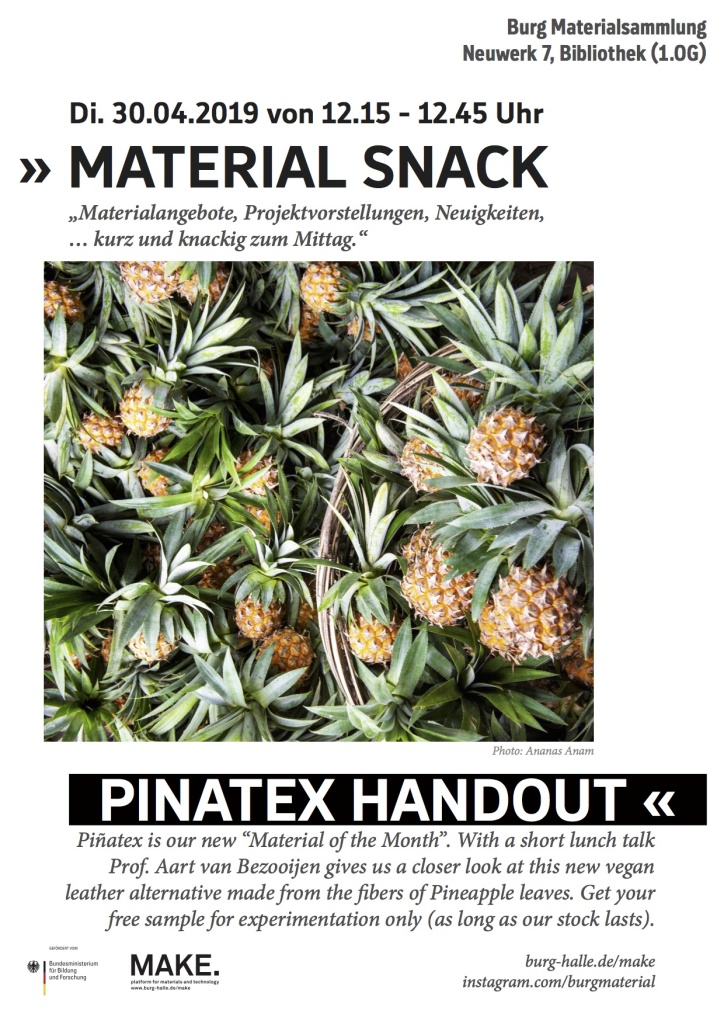

– Material of the Month: Piñatex Vegan Leather Alternative

– Material of the Month: ThermHex Honeycomb Panels

2018

– Material of the Month: RELEA Recycled Leather

– Material of the Month: Precious Plastic

2017

– Material of the Month: Corn-based Bricks

– Material of the Month: Stone Paper

2016

– Material of the Month: Dutch Design Trash (Reuse)

– Material of the Month: Concrete Canvas

2015

– Material of the Month: Used Truck Tarps supported by FREITAG

– Material of the Month: Seaweed (with Julia Lohmann)

– Material of the Month: Mushroom (Die Welt)

– Material of the Month: 3D Printing (at the Digitale Werkstatt)

2014

– Material of the Month: Salt (Video)

– Material of the Month: Polycaprolactone (Video)

– Material of the Month: Beeswax (Video)

– Material of the Month: Tyvek (Video)

2013

– Material of the Month: Latex (Video)

– Material of the Month: Bamboo (Video)

– Material of the Month: Acrylic One (Video)

– Material of the Month: Kraftplex (Video)

Materialautomat @Burg Galerie

Material of the Month: Scrap Glass + Workshop

Einführung in das Material Glas im Hinblick auf das Thema „Circularity“

Inhalte

– Werksbesichtigung von industriellen Produktionen unter dem Punkt der Nachhaltigkeit

– Vortrag von Re³Glass (Save the Date: 12.12.2019)

– Querschitte zum DIY Umgang mit dem Material Glas

Recycling von Glas

– arbeiten mit gefundenem Glas als Ressource am Fusingofen

– denkbare Techniken: biegen, fusing und absenken

– maximale Größe in der Fläche sind ca. 30 x 30 cm

Upcycling von Glas

– die kalte Nachbearbeitung von Glas zur Weiterentwicklung

– denkbare Techniken: sägen, schleifen und sandstrahlen

Fakten

– Zeitraum: 9. – 13. Dezember (Ofenstart Freitag 13. Dezember)

– Ort: Bild Raum Objekt Glas (Werkstatt Kurvenburg)

– Teilnehmende: Max. 8 Student*innen aus Kunst und Design

Anmeldung bis 30.11.2019

Die Anmeldung erfolgt per Email über make(at)burg-halle.de Bitte mit angeben:

– Name, Studiengang und Studienjahr, Matrikelnummer

– Dein Vorhaben (“Was würdest du gerne machen?”, “Mit welche Glasobjekten würdest du Arbeiten?” in 2-3 Sätze oder als Skizze)

– In KW49 werden die Teilnehmer*innen bekannt gegeben

Material of the Month: Hanji + Workshop

Der Workshop findet von Dienstag bis Donnerstag 18.- 20. Juni jeweils von 9.30 – 16.30 im Südflügel / Atelier II statt.

Verbindliche Anmeldungen bitte bis zum 10. Juni 14. Juni unter: kroepelin(at)burg-halle.de oder make(at)burg-halle.de

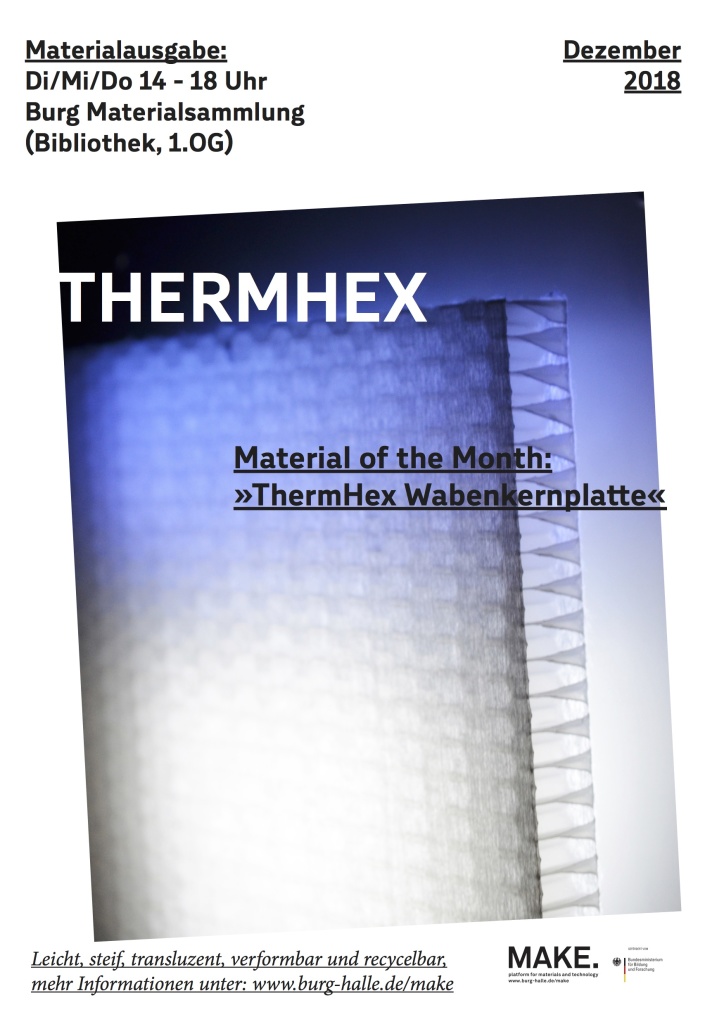

Material of the Month: ThermHex Honeycomb Panels

We are excited to demonstrate ThermHex Honeycomb Panels as Material of the Month. These next generation materials have a few promising qualities compared to solid panels (such as wood). The inner honeycomb structure provides the material both lightness and structural stability. The open (airy) structure and translucency of the material goes well in combination with (colored) light. Finally, the whole panel is made of a single polypropylene material, a thermoplastic which is recyclable and easy to (heat) transform.

Kick-Off Workshop this Tuesday: From 13.00 – 18.00 we are exploring its construction-lightness, light-translucency, heat-transformation and gather ideas for joints/connections with other materials. Students from all departments are welcomed to join us in getting hands-on with these ThermHex honeycomb panels.

Get your own (free) material samples for experimentation at the Burg Material collection.

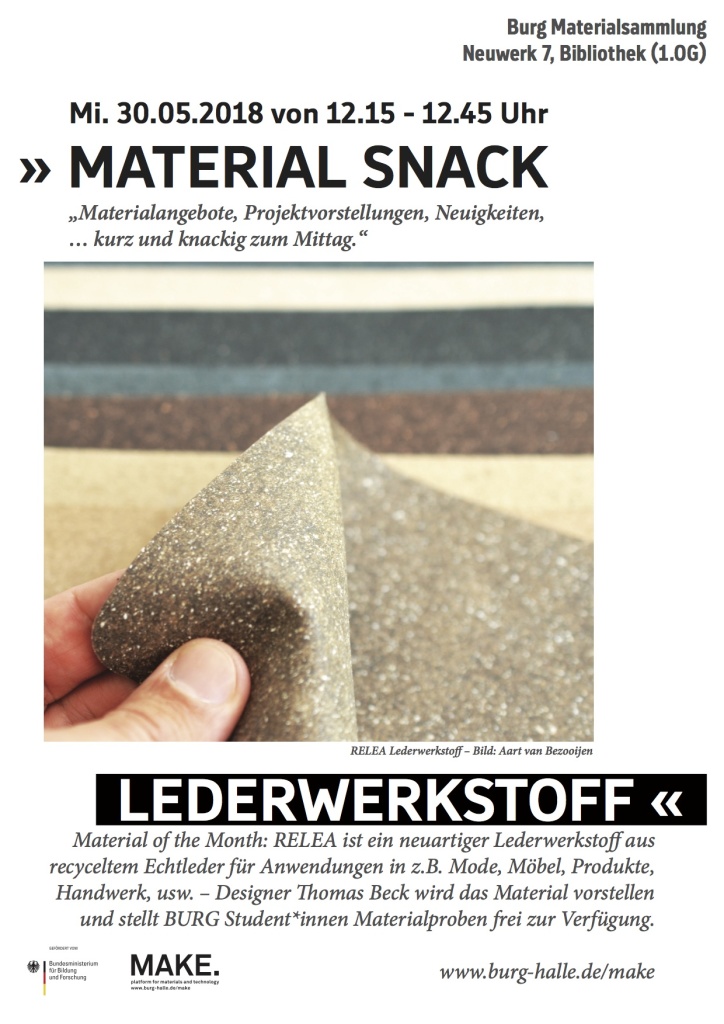

Material of the Month: Recycled Leather

Our next Material of the Month is a new type of leather material called “RELEA”. The material is made of recycled leather scrap for applications in fashion, furniture, products, crafts and more. – Designer Thomas Beck will be presenting the material and provides BURG students (free) material samples for experimentation.

Best Wishes for 2018

Best Wishes from all of us at MAKE. – Aart, Benno, Lorenz, Michael, Ulrike and Valena

Materials: styrofoam (base), wood (lettering), salt (surface) from Saline Halle

Prototyping: Michael Krenz and Oliver Reinecke

Video: Aart van Bezooijen

Material of the Month: Corn-Based Brick (Competition)

MAKE. invites you to the “MAKE. A LITTLE SPACE, MAKE. A BETTER PLACE” competition. We are offering some 25,000 corn-based bricks that stick together if you moisten them lightly. This corn-based foam is biodegradable and dissolves in water.

Which place of town would you like to transform? Those empty houses, never-ending construction sites or grey walls? Join us in making Halle more colourful – and send photos of your intervention to: make (at) burg-halle.de

Don’t forget to include your name(s) and title of your work to participate in the competition. The street art experts from the Freiraumgalerie are supporting us to select the award winning entries.

These colorful corn-based bricks are available for all students as long as our stock lasts.

Please help yourself at the Villa Foyer (Neuwerk 7) or at the Burg Mensa (Seebener Straße 1).

A few important facts:

Deadline for your photos: 09.07.2017

Awarding during “Jahresausstellung”

Jury: Freiraumgalerie